Understanding Approach

When you learn about plastic injection moulding approach, what’s first thing that kitchen sinks into your mind? Probably, you might consider it as one thing really overwhelming but do not you are aware that today, it really is now thought to be a truly gratifying but challenging occupation? This process has filled with options and also advancing.

Plastic injection moulding is actually a process in which plastic parts are made. We all know, plastic is inexpensive and adaptable items that is used practically in just about every corner from the world. Definite instances of injection-moulded plastic materials will be the keyboards, computer mouse, and the ones plastic soda pop bottles you have daily.

The Procedure

To a determined individual, the procedure of plastic injection moulding may be simple specifically once furnished with high quality tooling. The method begins with form preparation. In this article, plastic pellets are fed on the huge pot known as auger or attach, that is driven by a hydraulic. Once the auger within the tube converts, the pellets are fed around the auger’s lines until the pellets are dissolved.

Following is definitely the injecting from the dissolve in to the mildew. The dissolved plastic is located or administered into a divide-die mold. Inserting is done once the auger forces ahead the moulds through the help of a higher pressure about ten thousand to 30,000 psi. Then, the injection mould solidifies and sets apart alone in the tube. This stage of the procedure is named solidification.

Now, the mould is able to awesome forming into its wanted style or design. This air conditioning procedure may be the longest period. Essentially, it uses about 85 % of your overall period’s time. After solidification, the fungus goes through the process of demoulding or unloading. Right here, the molds clamp is launched to permit the molds ejection. Then your pattern is recurring.

Layout Things to consider

When thinking about injection moulding designs, each and every style has to acquire angled surface areas. The purpose of this is certainly to permit easy removing of the part in the mold. Normally, the perspectives need to evaluate about 1 to 2 diplomas for area styles with a minimum of 5 various ins on its walls fullness. Like as an example in soft drink bottles, slender and thicker wall structure is economical and probable. Nevertheless for some other styles, make certain you have obtained standard wall surface size in your design’s area and ribs; it will be easy to conserve so much from your manufacturing attempts and costs.

Tooling

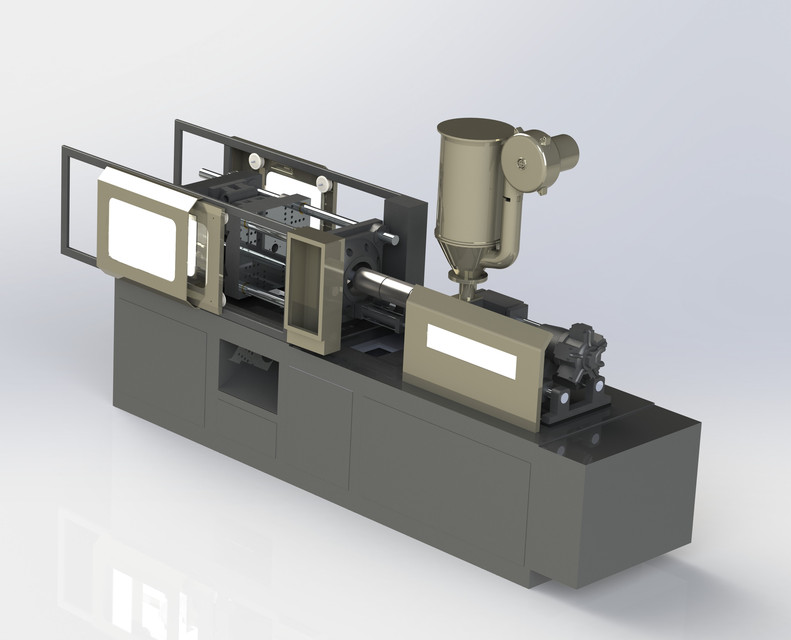

Injection moulding tooling is not an issue right now. Now there are quantities of mould tooling suppliers able to cater you the newest machines and application to meet your plastic moulding requires. Right now, no matter what your design and style is, you can get an injection moulding device without having them run for re-planning. In the event there are specific changes about the styles, the changes are only minimal and primarily for your own benefit instead of theirs.

Genuinely, there are numerous items to take advantage of in this kind of career. Nevertheless, before you bring them all, you need to take every one of the challenges behind the process. Have a great time!