Quick shot shaping is actually exactly what the brand shows, nevertheless repeated with a component of 10! It is sometimes complicated to picture that anybody could give a support that may ensure a totally doing work shot form in a day or two, however that is really the circumstance. This is absolutely what quick injections shaping is all about: fast, as with exceedingly speedy! These Pattern are made of high assessment aluminum and will supply anyplace from a number of parts to countless numbers. By and also by, I have taken a try at numerous lightweight aluminum condition that develop excellent parts considerably after a few a huge number of cycles. From your outset I had been remarkably wary, however subsequent quite a lengthy whilst of making shot forming models, It obtained regular.

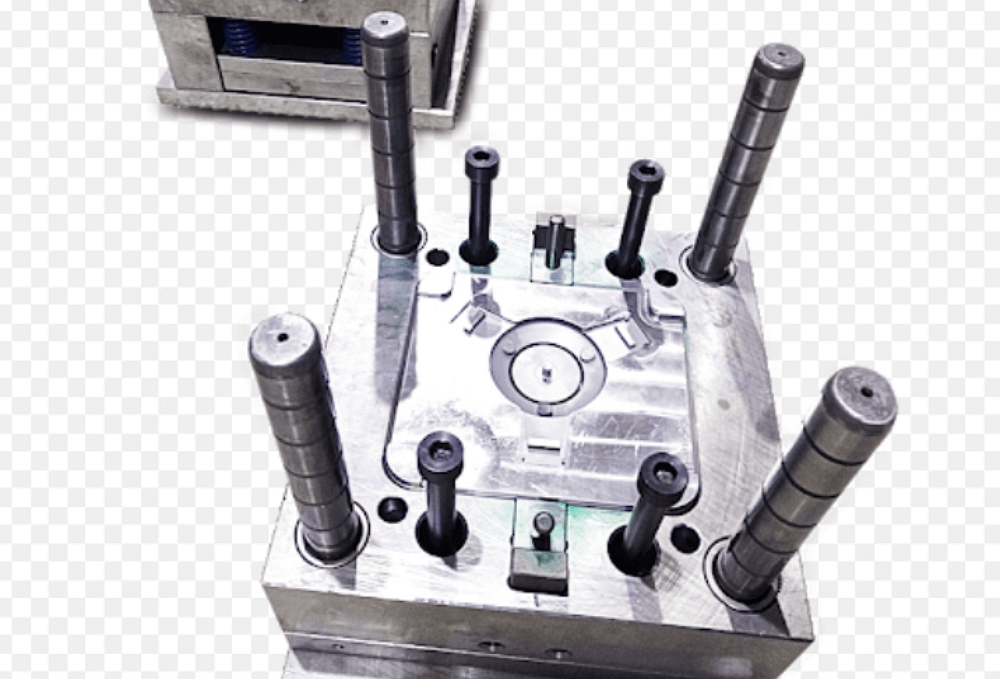

How can rapid injections generating operate? It functions via computerizing nevertheless significantly as could realistically be needed inside the develop generating method. If you take the buyer is 3-D design and mechanizing the program and manufacture of the shape, the direct instances are sliced as a result of a modest amount of the regular method. One of the central components of the robotization procedure is in the structure of the plastic-type material aspect. By working with learned fashioners, quite a few illustrates, for instance, undermines, could be minimal or washed out. A procedure for link up the postpone among model and whole production. Around the away from possibility that you require a working injections form on the provide time, this is basically the proper reaction speedy tooling.

Short run production to get your piece within the industrial middle right away. Gives technicians a working model to manoeuvre to an out and out construction for the creation musical instrument.

Exactly what are the troubles of fast injection generating? The rapid tooling are low design. Works the best for far more straightforward elements with minimal area action and undermines. EDM machining is murdered, alongside these collections some fine detail could possibly be relinquished. The entire centre and pit are speedy CNC machined, frequently on 5-hub CNC models, along these facial lines the blueprint has constraints.

Is rapid injections developing expensive? Shockingly, the expense is quite sensible, however there may be regularly limited to pay for remarkably fast turnaround. Frequently even so, the expense is quite a bit under can be standard. This is because of the extremely developed robotization process of this kind of shape generating. Rapid shot shaping is actually a specialized market section of shot from producing. It assists a profoundly particular business heart, nevertheless is substantial in the specialty. The capacity to get your injections shaped plastic-type material part to market remarkably quick is fully crucial that you the advantage firm. Also, the ability to get over any shield among product and high design is an exceptionally important apparatus for custom made injection decays.